| image | Series | Features | Description | catalog | Specification | RoHS | REACH | Part No. | Application |

|---|---|---|---|---|---|---|---|---|---|

|

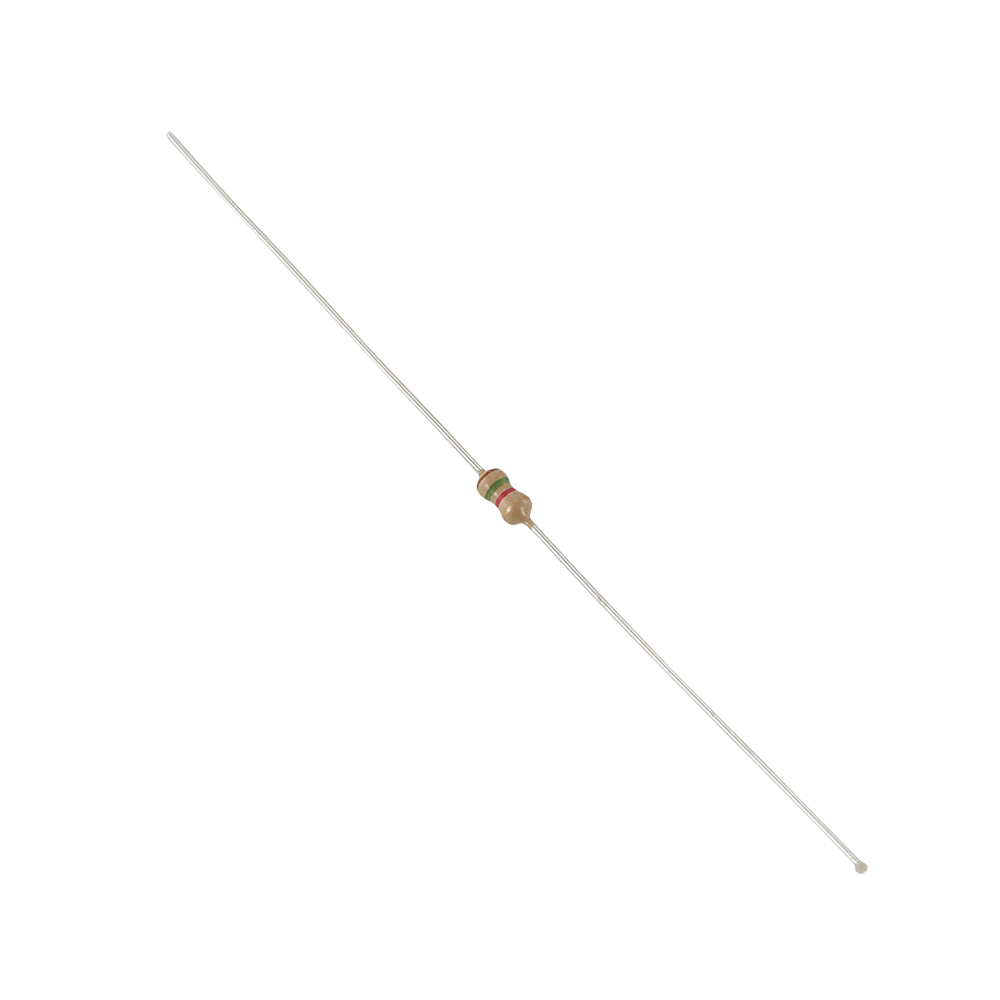

RD | Carbon Film Resistor |

|

Application Guide | |||||

|

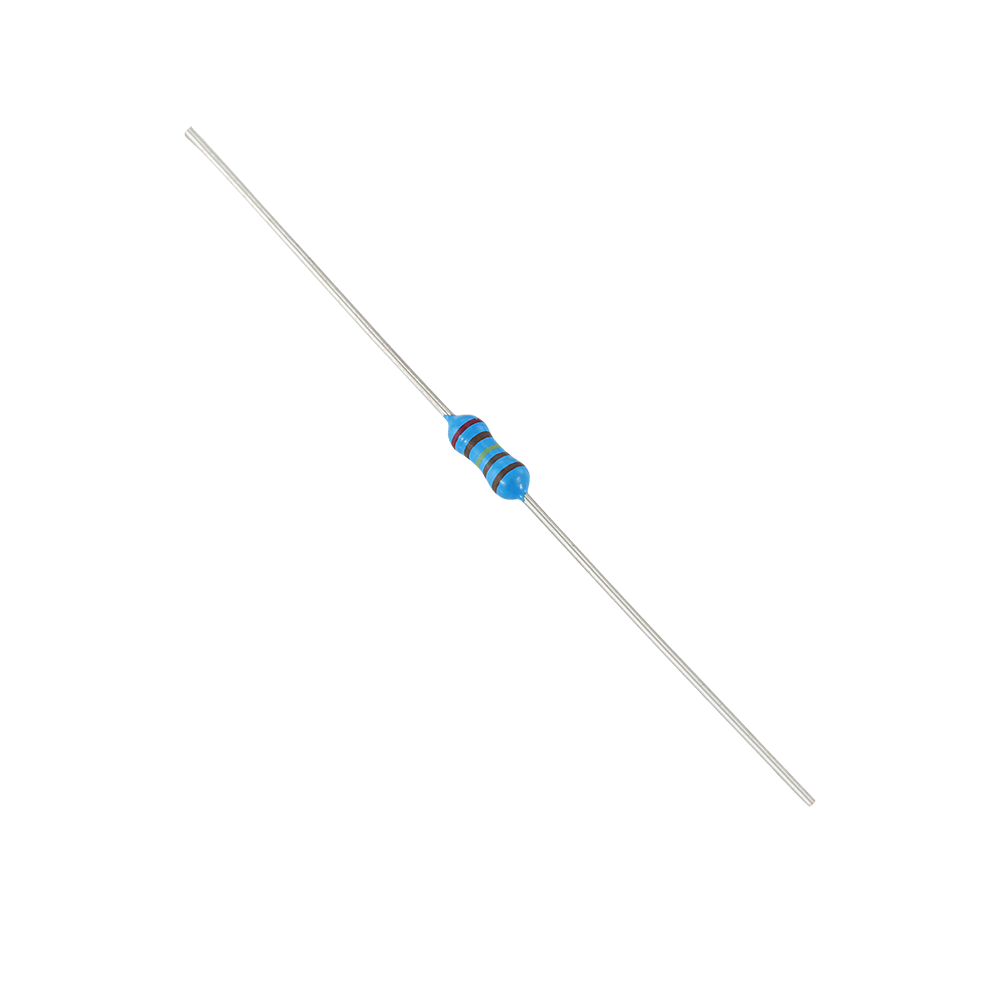

RN | Precision Metal Film Resistor |

|

Application Guide | |||||

|

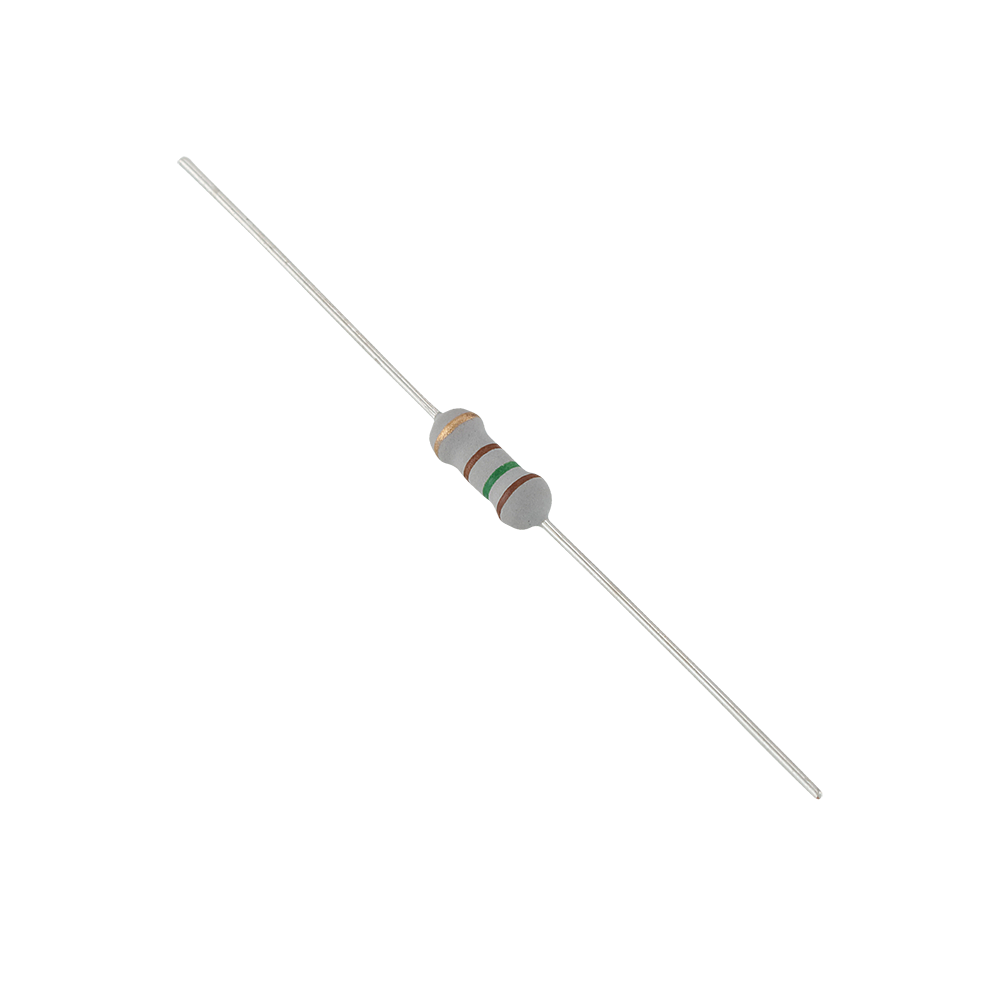

RSU | Metal Oxide Film Resistor(ultra Small Type) |

|

Application Guide | |||||

|

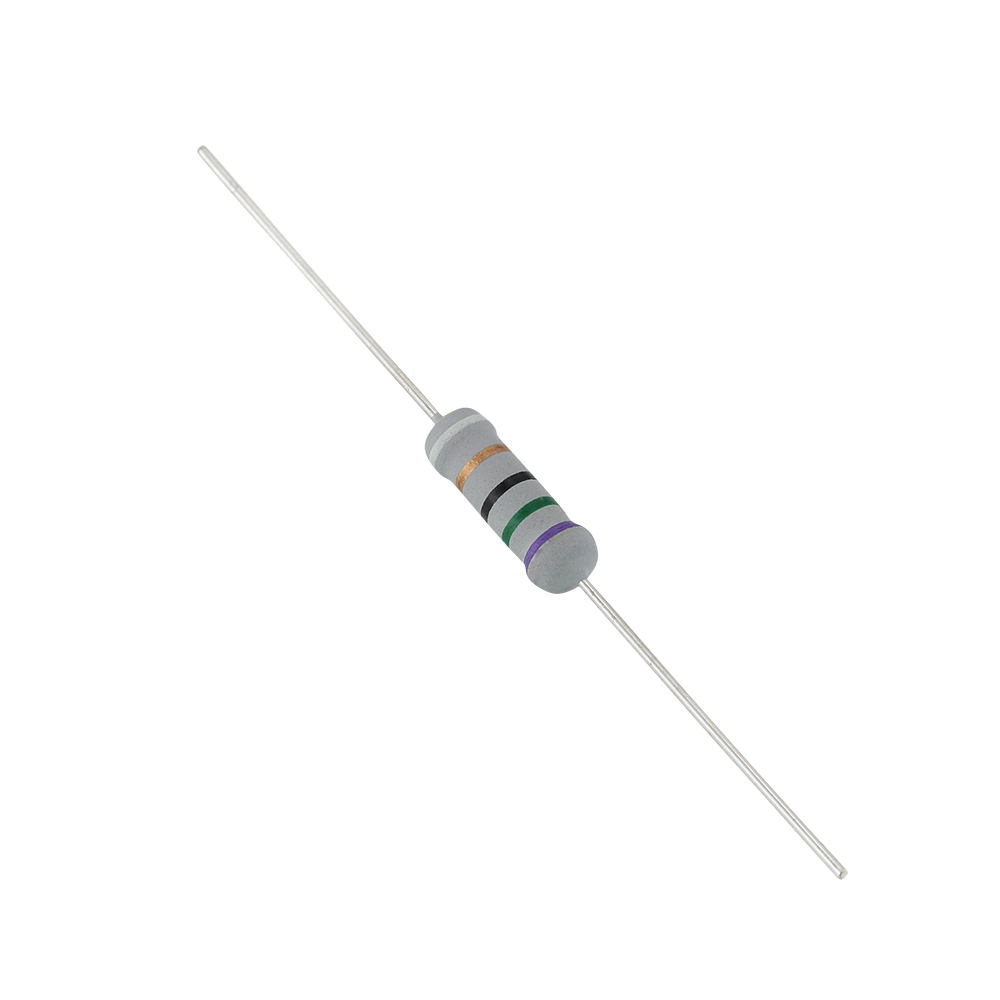

RSNF | Anti-Pulse Non-Inductive Resistors |

|

Application Guide | |||||

|

RSSF | RSSF Anti-Pulse Non-Inductive Resistors(Small Tyep) |

|

Application Guide | |||||

|

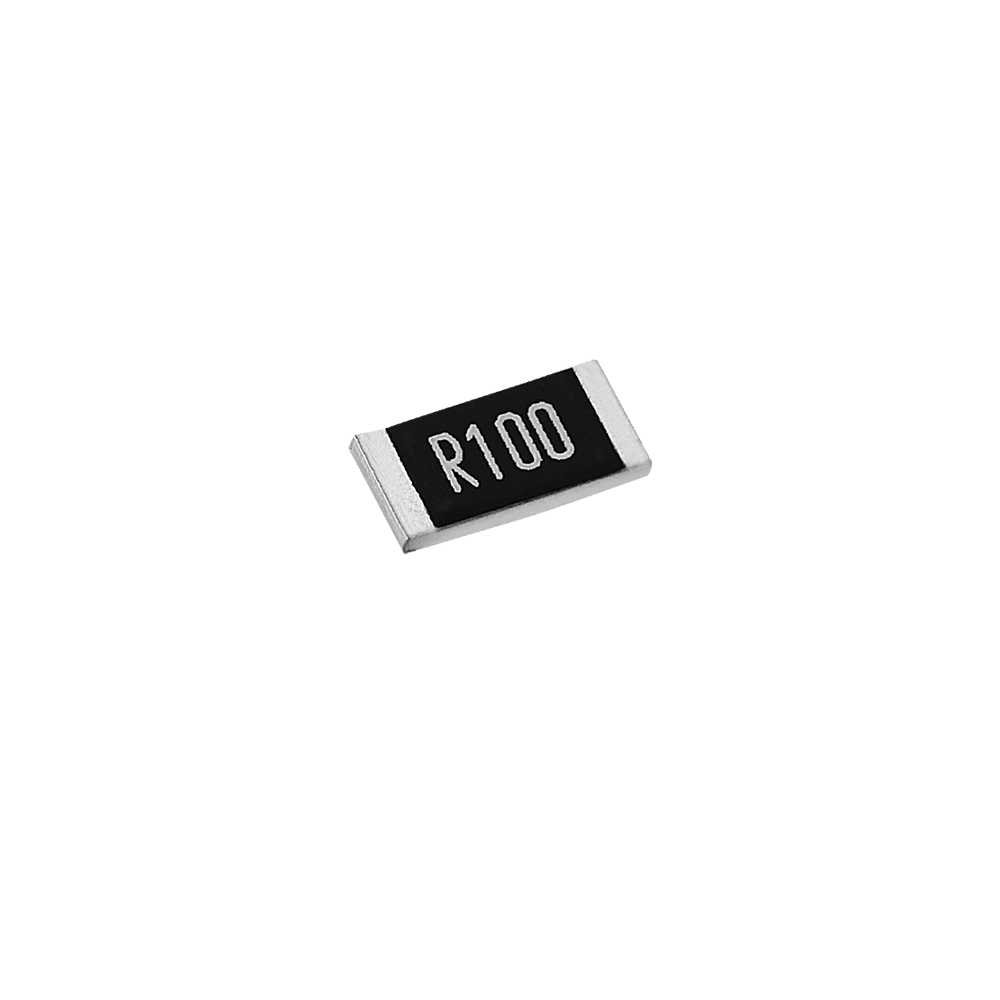

CLG | Thick Film Low Ohm Chip Resistors(High power rating and low TCR ) |

|

Application Guide | |||||

|

CPB | Current Sensing Thick-film Power Sulfur Resistors Metal Paste | Application Guide | ||||||

|

FKN | Fusible Wire Wound Resistors,Flameproof |

|

Application Guide |

Wire Precision Resistor is wirewound resistors that are designed to have a very precise and stable resistance value. These types of resistors are used in applications where a high degree of accuracy is required, such as in measurement and testing equipment, precision instrumentation, and control systems.

To achieve a high level of precision, precision wirewound resistors are typically made with high-quality resistive wire and carefully wound to precise tolerances. They may also be made with more advanced winding techniques, such as helical winding or multi-layer winding, to improve stability and reduce temperature coefficient.

In addition to their precise resistance value, wire precision resistor may also have other features that improve their performance, such as a low temperature coefficient, a high power rating, and a low inductance. These characteristics make them well-suited for use in a wide range of applications.

Wirewound resistor construction varies widely. The fabrication method and material selection depend on how the resistor will be used in the circuit. All of these are made by wrapping wire around an iron core. The resistance value depends on the resistivity, cross-section and length of the wire. Since these parameters can be precisely controlled, high precision resistors can be obtained. For high tolerance requirements, measure the resistance value to accurately determine the length of the cutting line. To produce high resistance, the wire diameter needs to be very small and very long. Therefore, wirewound resistors are mainly produced for lower resistance values. For low power ratings, use very thin wire. Handling of very thin wires is critical. Any damage could cut the wire. After winding,

There are also wirewound resistors rated up to 50 W or more. The construction of these resistors is completely different. Compared to other resistor types such as metal film, the wire diameter is relatively larger and therefore stronger. We offer over 20 different series of wirewound constructions. Selection can be made according to installation, application and resistance range. They all have good stability and resistance range, and come in a variety of wattage specifications.

Read More