| image | Series | Features | Description | catalog | Specification | RoHS | REACH | Part No. | Application |

|---|---|---|---|---|---|---|---|---|---|

|

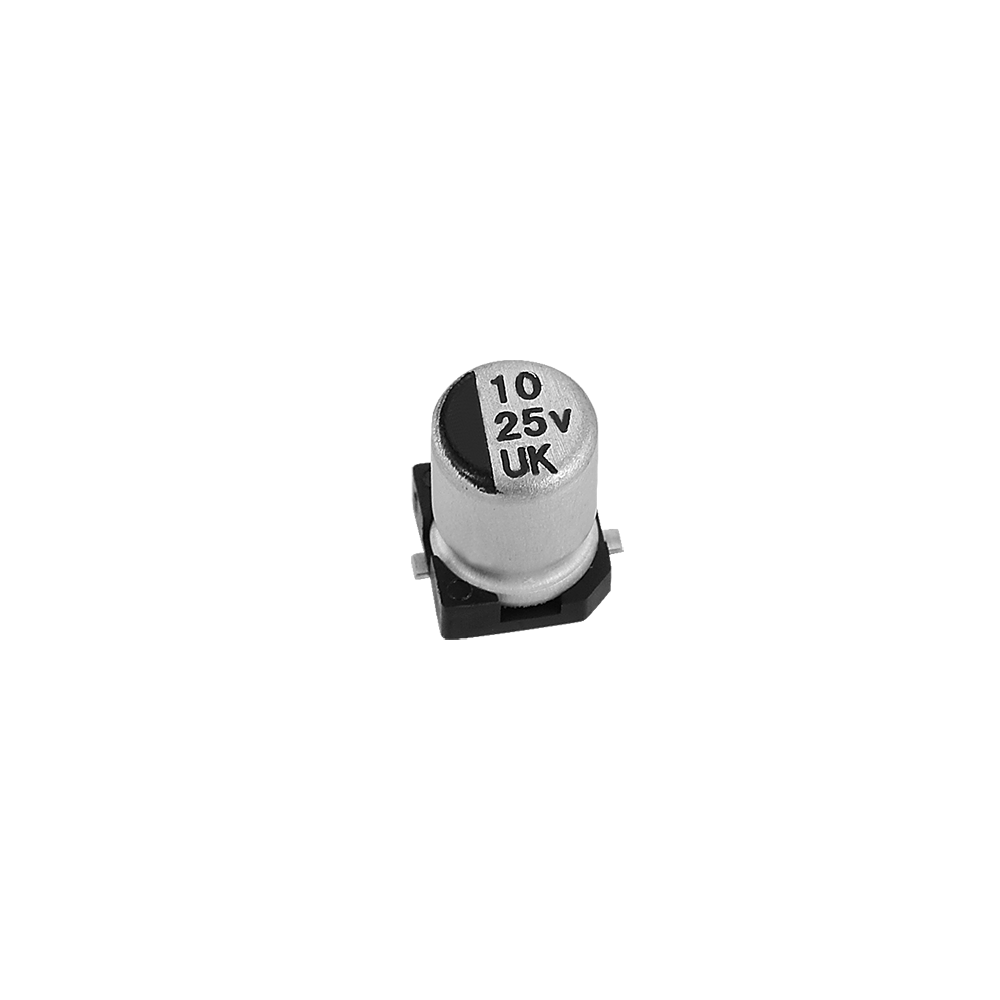

CDUK | Low leakage current |

|

CDUK | Application Guide |

The conductive plate of a capacitor is separated by a dielectric material. This material does not provide perfect insulation and allows current to leak through it. The DC leakage current is this small current that flows through the capacitor when a voltage is applied. The value of this current depends mainly on the applied voltage, the temperature of the capacitor and the charging time.

Depending on the characteristics of the dielectric material and construction, the leakage current varies depending on the type of capacitor. Aluminium electrolytic capacitors have a high leakage current, while ceramic, foil and plastic film capacitors have a low leakage current. The very small leakage currents are often referred to as "insulation resistance".

Capacitors are used in a wide range of applications in electronic circuits, including decoupling, filtering and coupling applications. Some applications, such as power supply systems and amplifier coupling systems, require capacitors with low leakage currents. Aluminium electrolytic and tantalum capacitors have high leakage currents and are generally not suitable for such applications. Plastic and ceramic capacitors have lower leakage currents and are typically used in coupling and storage applications.

The dielectric materials used in capacitors are not ideal insulators. For various reasons specific to each dielectric, small DC currents can flow through or "leak" through the dielectric material. As a result, when a capacitor is charged to a certain voltage, it slowly loses its charge. As it loses its charge, the voltage between the capacitor electrodes drops.

Read More