There are four main types of chip inductors, namely wire-wound, laminated, woven and thin-film chip inductors. Two types of wire-wound type and laminated type are commonly used. The former is a product of the miniaturization of traditional wire-wound inductors; the latter is made with multilayer printing technology and laminated production technology, and its volume is smaller than wire-wound chip inductors. It is a key product developed in the field of inductive components.

1. Winding type

It is characterized by a wide range of inductance (mH~H), high inductance accuracy, low loss (large Q), large allowable current, strong manufacturing process inheritance, simplicity, and low cost, but its shortcomings are further Miniaturization is limited. The ceramic core winding type chip inductor can maintain a stable inductance and a fairly high Q value at such a high frequency, so it occupies a place in the high-frequency circuit.

TDK's NL series inductors are wire-wound type, 0.01~100uH, accuracy 5%, high Q value, which can meet general needs.

NLC type is suitable for power circuit, rated current can reach 300mA; NLV type is high Q value, environmental protection (reconstituted plastic), and can be interchanged with NL; NLFC has a magnetic screen and is suitable for power cords.

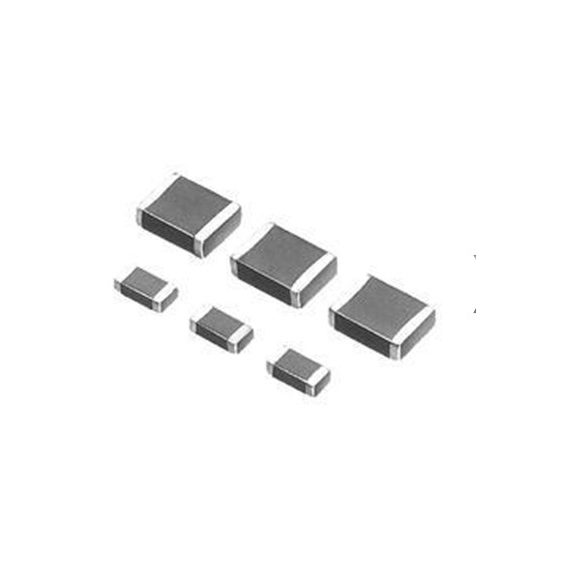

2. Laminated type

It has good magnetic shielding, high sintering density and good mechanical strength. The disadvantages are low pass rate, high cost, small inductance, and low Q value.

Compared with wire wound chip inductors, it has many advantages: small size, which is conducive to miniaturization of the circuit, closed magnetic circuit, will not interfere with surrounding components, and will not be interfered by neighboring components, which is beneficial to components High-density installation; integrated structure, high reliability; good heat resistance and solderability; regular shape, suitable for automated surface mounting production.

TDK's MLK type inductor has small size, good weldability, magnetic screen, high-density design, monolithic structure, and high reliability; MLG type has a small inductance, uses high-frequency ceramics, and is suitable for high-frequency circuits; MLK type working frequency 12GHz, high Q, low inductance (1n~22nH)

3. Thin film type

It has the characteristics of maintaining high Q, high precision, high stability and small size in the microwave frequency band. The internal electrodes are concentrated on the same layer, and the magnetic field distribution is concentrated, which can ensure that the device parameters after mounting do not change much, and show good frequency characteristics above 100MHz.

4. Braided

The characteristic is that the inductance per unit volume at 1MHz is larger than other chip inductors, small in size, and easy to install on the substrate. Used as a miniature magnetic component for power processing.

In actual applications, the application should be selected according to the situation, the application effect should be considered, and the material cost should also be considered.