Electricity has become an indispensable part of our daily life, and the use of electricity is more and more extensive, but the existence of electricity also has a certain degree of danger. The higher the current, the greater the danger, so the use of wire-wound resistors The role is highlighted.

What is a wire wound resistor:

Wire-wound resistors are constructed by winding resistance wires on an insulating frame. The resistance wires are generally made of nickel-chromium and manganese-copper alloys with a little resistivity. The insulating frame is made of ceramic, plastic, metal coated with an insulating layer and other materials into a tube shape, a flat shape and other shapes.

The resistance wire can be wound into one layer or multiple layers on the frame as required, or a non-inductive winding method can be used. This kind of resistance is divided into fixed and variable. It is characterized by strong working stability, good heat resistance, small error range, and the resistance value can be accurate to 0.001 ohms, but the price is relatively expensive, most of which are used in medical equipment, and the rated power is generally above 1 watt.

The value of the winding resistance is accurate. In theory, unless it is used as a charger output voltage reference, the general charger does not need a winding resistance. The charger circuit is an SMPS switching power supply circuit. The high-voltage end signal generation circuit has high requirements. It is impossible to use winding resistors, otherwise it will cause overexcitation, which will affect the oscillation frequency and cause large output fluctuations. Only the low-voltage end sampling reference Circuits may use wire-wound resistors.

Features of precision wire wound resistors:

The resistance of precision wire wound resistors can range from a few tenths of ohms to tens of megaohms, and the accuracy can reach more than ±0.01%. The temperature coefficient of resistance can be less than 10ppm/K, and the long-term stability of resistance can be less than ±0.005%/year. The disadvantage is that the high frequency performance is poor, but the non-inductive wire winding method can be appropriately improved.

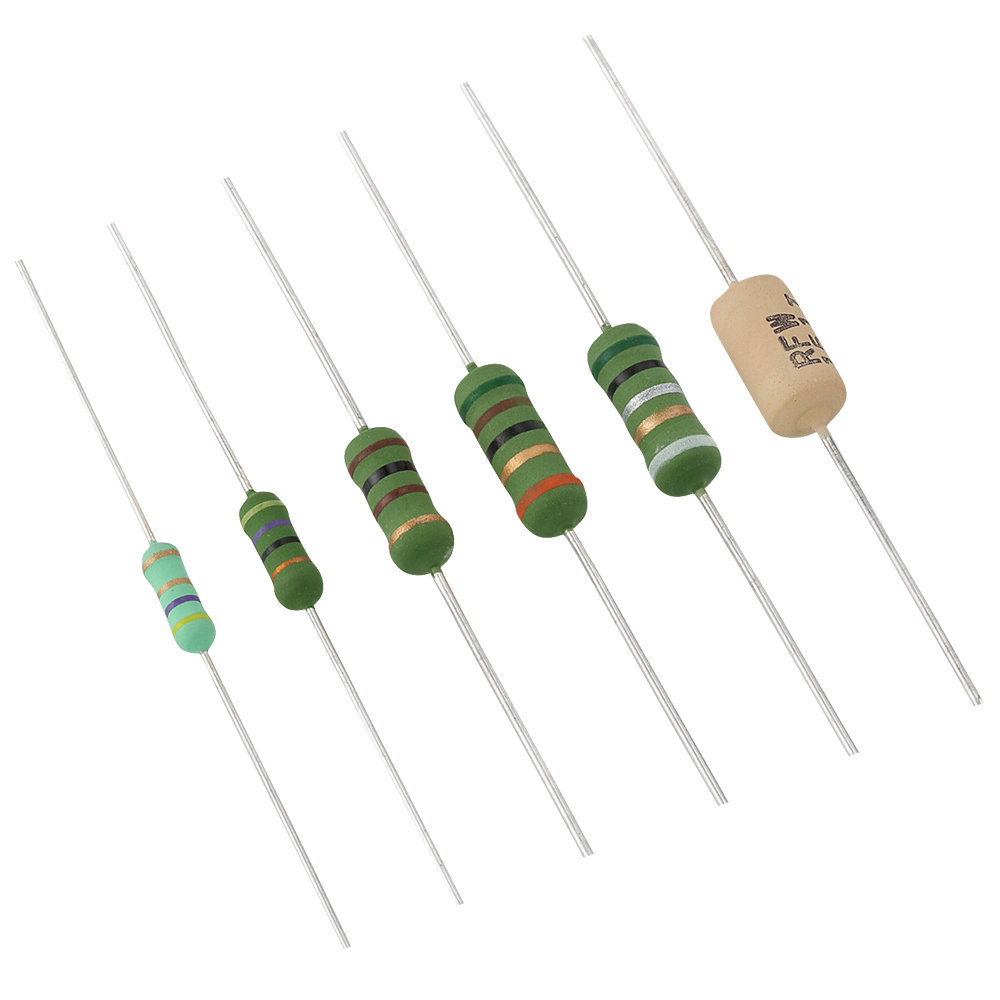

Packaging methods of precision wire wound resistors:

According to the sealing method, precision wire wound resistors are generally divided into epoxy glass steel pipe sealing, aluminum housing sealing and plastic housing sealing.

What are the advantages and disadvantages of wire wound resistors:

Wire-wound resistors are made of nickel-chromium wire, manganese-copper wire, and constantan wire wound on a porcelain tube. They are divided into two types: fixed and adjustable.

The advantages of high-power wire-wound resistors: high blocking accuracy, low noise during operation, stability and reliability, low-temperature coefficient, can withstand high temperatures, and can still work normally at an ambient temperature of 170 degrees Celsius.

Disadvantages of wire-wound resistors: large size and low resistance, most of which are below 100KΩ. In addition, due to structural reasons, its distributed capacitance and inductance are relatively large and cannot be used in high-frequency circuits. Therefore, the winding resistance acts as a choke to the current, making it difficult for the current to pass.

Aillen is a professional passive electronic component manufacturer. You are welcome to discuss the knowledge of electronic components together. Our aim is to make progress together, produce better products and provide better services,welcome to contact us.